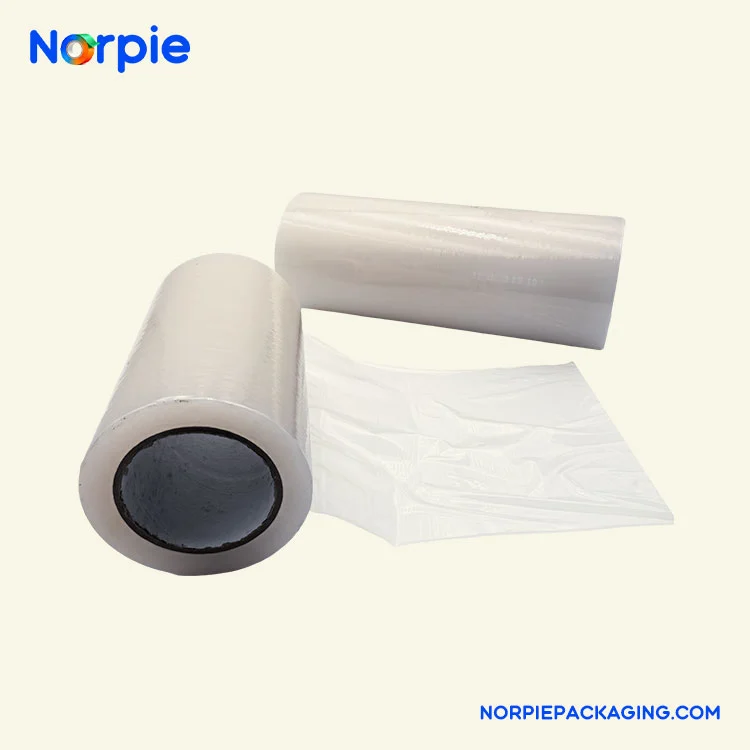

Packaging Roll, as the name suggests, is a thin film material used to wrap, protect, and seal items. It is typically made from one or more polymer plastics (such as polyethylene PE, polyvinyl chloride PVC, polypropylene PP, etc.) through processes like blow molding or cast coating.

Protect Products: Prevent products from being contaminated or eroded by dust, moisture, grease, oxygen, etc., and prolong the shelf life (especially food).

Fix and Stabilize: Bundle multiple scattered items together for easy transportation and handling, such as pallet wrapping film.

Improve Safety: Prevent the product from scattering and damage during transportation, and have anti-theft function (such as shrink film makes it difficult to open and restore the package).

Marketing and Display: Transparent or well-printed packaging film can improve the appearance of the product, display brand information and attract consumers.

Freshness: For fresh food, a specific packaging film (such as plastic wrap) can regulate gas exchange and keep the food fresh.

There are many kinds of packaging films, which can be classified according to materials, functions and forms.

PE (Polyethylene) Film: The most common packaging film.

Features: Soft, good toughness, no smell, low cost.Usage: Stretch wrapping film, plastic film, plastic bag, inner lining of bubble film, etc.

PVC (Polyvinyl Chloride) Film:

Features: High transparency, good gloss, high shrinkage rate.Application: Primarily used for heat-shrink packaging, such as beverage bottle labels, electronics, cosmetics, and other external packaging. Note: Some PVC films may contain plasticizers and should not be in direct contact with food.

PP (Polypropylene) Film:

Features: High transparency, good rigidity, high temperature resistance, environmental protection.Application: Widely used for high-transparency packaging in apparel, textiles, and food products. BOPP (Biaxially Oriented Polypropylene) film is the most common type, commonly used for packaging biscuits and snacks.

PET (Polyester) Film:

Features: High strength, high hardness, high temperature resistance, good barrier.Use: Electronic products, high-end gift shrink packaging, and the outer layer of composite packaging materials.

POF (Polyolefin) Heat Shrink Film:

Features: Environmentally friendly and non-toxic, excellent toughness, high shrinkage rate, soft surface gloss.Application: Widely used in food, cosmetics, stationery, medicine and other fields as a set package, it is an excellent substitute for PVC heat shrink film.

PVDC (Polyvinylidene Chloride) Film:

Features: Excellent barrier to oxygen and water vapor.Use: Mainly used for food packaging that needs long-term preservation, such as ham sausage, cooked food products, etc., usually as a layer of composite film.

It is self-adhesive and can be wrapped around goods (especially pallet goods) by mechanical or manual stretching, using its elastic contraction force to tightly wrap the goods together.

The packaging is slightly larger than the product in size. After heating by the heat shrinker, the film will shrink rapidly and adhere tightly to the surface of the product. It is commonly used for the collection packaging of multiple products or the outer packaging of a single product.

It is mainly used for food preservation in households and supermarkets, covering the surface of containers or food to prevent moisture loss and flavor transfer.

The film in the middle is full of air bubbles, which has good buffering and impact resistance, and is mainly used to protect fragile items.

When used with vacuum packaging machine, the air in the bag is extracted and sealed. It is mainly used for the preservation of meat, seafood and other food to prevent oxidation and microbial growth.

Is this fixed pallet cargo? → Select stretch wrap.

Is it about creating a sleek product packaging or a bundled package? → Opt for heat shrink film (POF/PVC/PET).

Is it about preserving packaged food? → Opt for high-barrier films like PE cling film or PVDC.

Is it for protecting fragile items during transport? → Choose bubble wrap.

Shape and Weight: Standard or custom? Heavy-duty packaging requires high-strength stretch films (e.g., linear low-density polyethylene (LLDPE)), while lightweight products can use standard polyethylene (PE) or polyolefin (POF) films.

Is it fragile or afraid of pressure? If so, you need a good cushioning performance of bubble film or thick wrapping film.

Environmental Sensitivity:

Concerned about oxidation or moisture? → Opt for high-barrier materials like PVDC, BOPP, or aluminum-coated film.

Need light protection? → Choose a printed or opaque film.

Does it require heat resistance (e.g., for cooking)? → Select heat-resistant materials such as CPP (Cast Polypropylene) or PET.

Manual Packaging or Automatic Machine Packaging?

Manual packaging: Low requirements for film tensile rate and self-adhesion.

Machine packaging: Requires a special film to match the equipment, and has strict requirements on the specifications and performance of the film (such as tensile rate and puncture resistance).

What's the Budget?

PE film is the most cost-effective, followed by POF, while PET and specialized functional films (e.g., high-barrier films) are more expensive. When requirements are met, select the product with the best cost-performance ratio.

Food Contact: The packaging film must be selected in accordance with the national food contact material safety standards (such as China's GB 4806 series) to ensure it is non-toxic and harmless.

Export Requirements: Exports to different countries/regions must comply with local regulations (e.g., REACH and RoHS in the EU).

Environmental and Sustainability: Consider using recyclable materials (such as single-material PE or PP films).